-40%

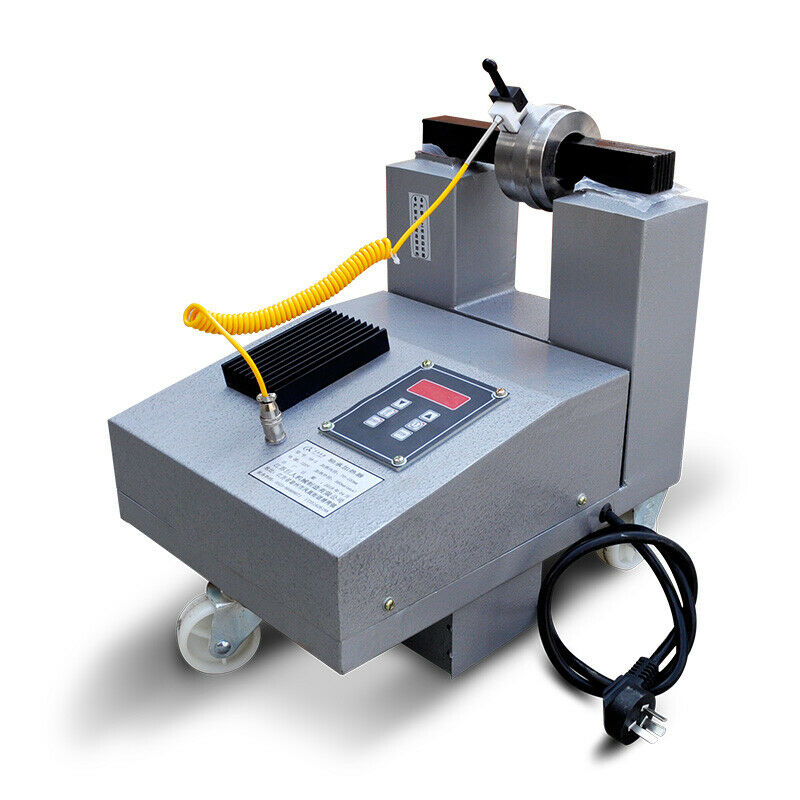

220V 5KW Electromagnetic Induction Heater Controller with SSR Control Modb RS485

$ 194.82

- Description

- Size Guide

Description

5kw Electromagnetic Induction Heater Main Controller with Temperature ControllerProduct advantages 1

Integrated with digital core controller and German Infineon IGBT frequency conversion driver, intelligent temperature control module control hot air output, over current, over-temperature protection; Heating coil short circuit, open circuit protection.

Product advantages 2

Variable frequency output can automatically adjust the output power according to the temperature; the cable itself does not generate heat and can withstand the high temperature below 1000 degrees Celsius, the design life of the main engine is more than 10 years, the heating system basically has no maintenance cost in the later stage. Under the same condition, it is more than 30% more energy-efficient than coal and 60% more energy-efficient than natural gas and fuel oil.

Product advantages 3

Electromagnetic induction heating, no open fire, no fire hazard, safe and stable; No waste gas, no oxygen consumption, no pollution

Wiring diagram:

Operation panel description:

The key to choosing an electromagnetic heater depends on these four points

1,Specialization: DSP high-speed operation control, digital programmable technology, high-speed optocoupler drive, open hardware architecture

2,Quality assurance: 15 years of careful development, EU CE certification, ISO9001 quality management certification

3,Stable performance: The half-bridge IGBT module is used as the main circuit structure, which can save power by 30% ~ 80%, and the thermal efficiency can reach 95%, which can be customized:

4,Worry-free after-sale: one year warranty, professional technical staff guidance, lifetime cost maintenance of wearing parts, after-sales customer service one-to-one tracking service:

Internal control board wiring and purpose:

Instructions

:1, Connect the power supply voltage of the cooling fan, but connect the 220V power when the fan is 220V, and connect the 380V power when the fan is 380V

2, Connected with cooling fan 220V / 380V (depending on the user, generally 380V)

3, When the external cooling fan is DC 24V, this interface is a switch that controls the 24V fan to work or stop. The two ends of the interface are actually the normally closed contact points of the relay output on the motherboard.

4, Dual AC 24V power supply (choose 4 or 5 when making half-bridge)

5, Dual AC 24V power supply (choose 4 or 5 when making half-bridge)

6, Single AC 16V power supply

7, Power indicator (red)

8, Work indicator light, flashing during standby, and always on (green) during work

9, External indicator light, led to the LED interface outside the chassis

10, The soft start interface is connected to the R / s interface outside the chassis (can be set to open or close work through F-20, factory default close work, open stop status

11, Finely adjust the power potentiometer. When there is a large deviation in power, this potentiometer can be adjusted appropriately.

The 12,32-bit high-speed DSP processor

13, Externally connected programmable operating display

14, Isolated RS485 communication interface

15, External load temperature detection interface 1, with an accuracy of ± 1 ° C (maximum 150 ° C) single-channel, default 1 is used to measure external working temperature

16, External load temperature detection interface 2, with an accuracy of ± 1 ° C (maximum 150 ° C)

17,Multi-function input interface (set by F-20)

(1)10K input for external connection potentiometer can adjust the power range from 20% to 100%

(2)Externally connected PID input (0 ~ 5V) input

Do infrared thermometer or thermocouple conversion voltage 0 ~ 5V input to achieve the display temperature and control power size (up to 1000ºC can be measured and displayed)

18, Connect the high-frequency Mutual inductor and pay attention to the direction. If the direction is reversed, the power is very small

19, IGBT module drive (when doing half-bridge, choose 19, 20 or 23, 24)

20, IGBT module drive (when doing half-bridge, choose 19, 20 or 23, 24)

21, Connected to high voltage DC bus

22, IGBT temperature sensor interface

23, IGBT module drive (when doing half-bridge, choose 19, 20 or 23, 24)

24, IGBT module drive (when doing half-bridge, choose 19, 20 or 23, 24)

25, Connected to high voltage DC bus

26,RS485 communication interface, connect A ,B

27, Externally connected K-type thermocouple

28, Externally connected 12V relay drives other required loads, synchronized with the fan start/stop of the machine

Application

Contact us

FAQ

Q: Is it easy for a new operator ?

A: Yes, this device easy operate and you will love it!

Q:Can I watch the heating test video before place order ?

A: Yes, you can!

Q: Do you have any Certification for entry EU market ?

A: We have CE certification, you can chat with me and get it.